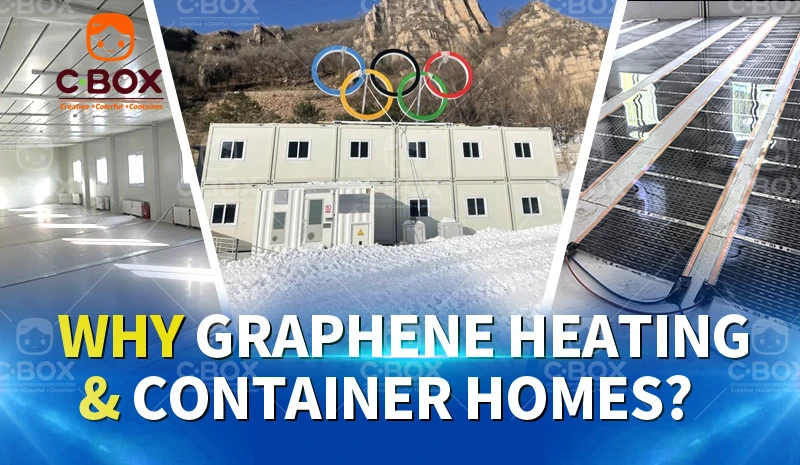

This article will explore the breakthrough advantages of this technology combination in depth and focus on the benchmark cases of the Winter Olympics competition area.

As the "king of new materials", graphene has become a revolutionary material in the field of electric heating films with its ultra-high thermal conductivity (about 5300 W/m·K), ultra-thin flexible structure and low energy consumption characteristics.

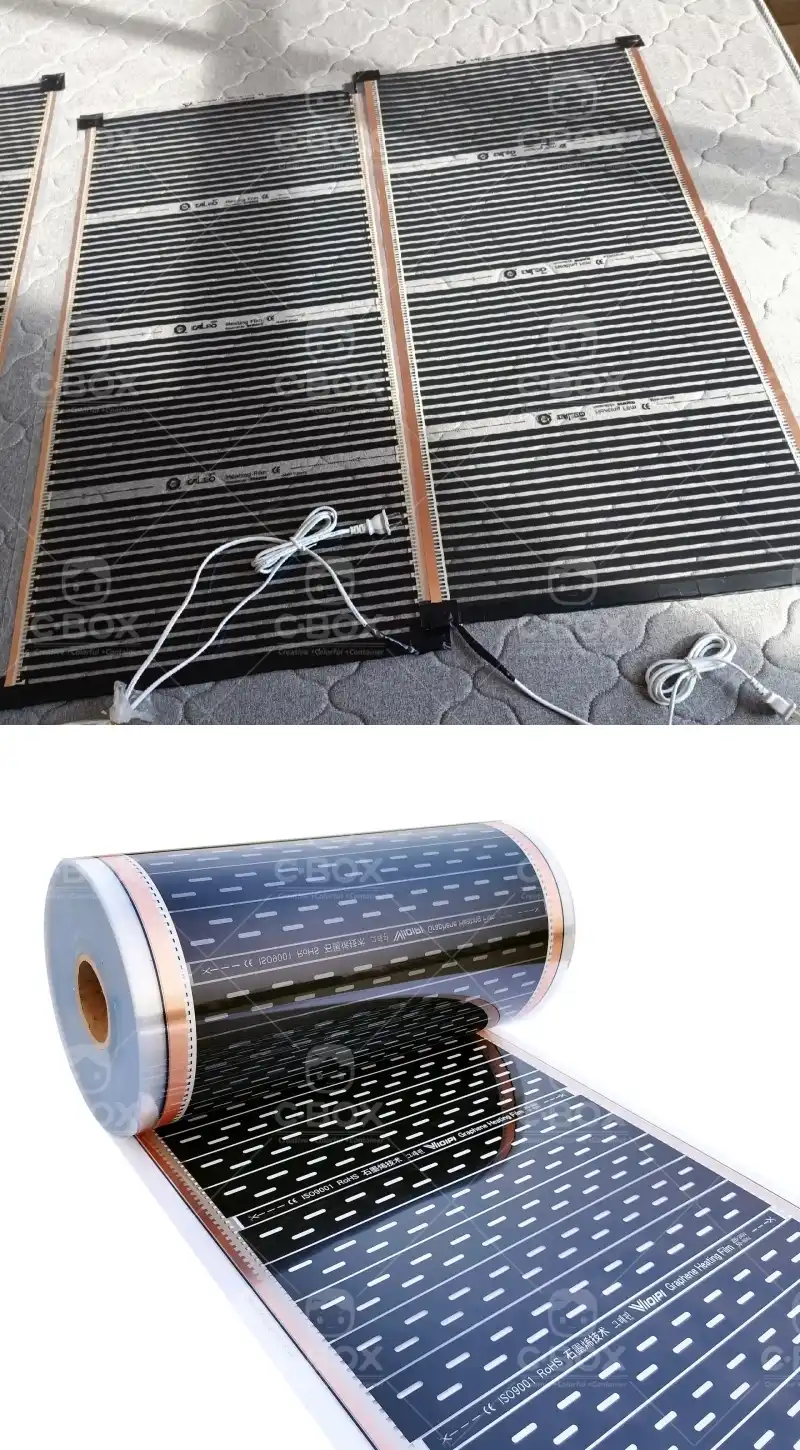

Graphene electric heating film is made of special graphene nano-carbon materials, metal copper foil current-carrying strips, PET, etc., and is a planar insulating conductive thin film made by a special lamination and bonding original process. It has excellent characteristics such as the largest thermal contact area and heat transfer efficiency, as well as highly uniform distribution of thermal contact surfaces. It can make the horizontal temperature distribution of indoor space more uniform and minimize the existence of hot and cold temperature zones in space.

The heating principle of graphene electric heating film: When the electric heating film is energized, the graphene nanoparticles produce "Brownian motion", and violent friction and collision occur between the particles. The generated heat energy is transmitted to the outside in the form of far-infrared radiation and convection.

Compared with traditional resistance wire or water heating system, graphene electric heating film has the following core advantages:

|

1. Comfort Heating is done by direct radiation of far infrared rays instead of heating the air, so the indoor air is fresh and will not cause indoor heat and dust; the heat radiates from bottom to top, forming a gradient difference from bottom to top, which makes the human body feel very comfortable, which is very consistent with the fundamental human health theory of traditional Chinese medicine that "the head should be cool and the feet should be warm". 2. Health The far infrared rays produced have a wavelength between 5-15um, which is called "life light wave" in medicine. People who are in such an environment for a long time can improve the microcirculation in the body and promote metabolism. 3. Energy saving Non-metallic surface material, large and uniform heating area, no loss, more than 90% electric heat conversion, is the material with the highest electric heat conversion efficiency, and has amazing energy saving effect. 4. Environmental protection The working state is silent, lightless, sewage-free, and no exhaust gas emissions. It is a veritable green and environmentally friendly product. |

|

5. Simple It can be cut to fit any occasion with an area of more than 1 square meter, and can be disassembled and reinstalled. The construction of 100 square meters is completed on the same day. 6. Repair-free The system does not require any cleaning, addition or replacement of materials and maintenance, and there is no human damage. It can be guaranteed for more than 50 years. 7. Safety The heating surface is corrosion-resistant, radiation-resistant, puncture-resistant, flame-retardant, with a maximum operating temperature of 60°C, and will not become a source of fire. 8. Beautiful It does not occupy indoor area and has the function of automatic leveling of the ground, which is conducive to indoor beauty and decoration. It is a product with the least impact on floor height. |

|

|

As a typical representative of modular buildings, container houses have the advantages of fast construction and flexible migration, but they have long been subject to three major problems: |

The intervention of graphene electric heating film just forms a targeted solution: |

|

1. Poor thermal insulation performance: The metal box conducts heat quickly, and the energy consumption of heating in winter surges; 2. Space limitation: Traditional heating equipment occupies the usable area; 3. Environmental pressure: Coal/oil heating produces carbon emissions. |

1. Ultra-thin embedding: Only 0.3mm thickness can be directly laid on the wall, floor or ceiling, saving 90% of equipment space; 2. Intelligent temperature control: Through the Internet of Things system to achieve zone temperature control, the actual energy saving rate of the Winter Olympics competition area reached 67%; 3. Whole house uniform heating: Far infrared radiation heat transfer eliminates cold and hot dead corners, and the body comfort is improved by 40%.

|

This project not only ensured the comfortable experience of more than 3,000 people during the competition, but also obtained LEED zero-carbon certification after the competition, becoming a global model for sustainable temporary buildings.

In the future, with the continuous upgrading of the industrial chain, this "golden combination" may lead the global transformation of the new generation of building heating systems.

Scan to messenger :